Product

제품

-

Analytical Products

- Wyatt Technology

- Awareness Technology

- Eurofins l Abraxis (GSD)

- Aurora Biomed

- Canada NRC-CNRC

- Chrom Tech

- Eichrom Technologies

- EPROGEN

- Fluidic Analytics

- Globe Scientific

- GENERON

- Halo Labs

- Hygiena International

- KROMATON

- InProcess-LSP

- MTC Bio

- MZ-Analysentechnik

- Newomics Inc.

- Occhio Instruments

- Optimize Technologies

- Pickering Laboratories

- PolyLC

- Raykol Group

- RheoSense

- Rocker Scientific

- Santai Science

- SEDERE

- Spectra Analysis

- UCT

- Wealtec Corp

-

Bio & Medical Products

- Biolog

- Adooq Bioscience

- A&A Biotechnology

- Accegen Biotechnology

- Anatrace

- Array Bridge

- Biogenes GmbH

- BioQuochem

- BioServ UK

- Biomiga

- Biotech Support Group

- CinderBio

- Cell Technology

- Creative Biolabs

- Creative Diagnostics

- Creative Biostructure

- Creative Biomart

- Creative Enzymes

- EICOM

- Emulseo

- GLYcoDiag

- Helix Biotech

- InnoGenomics

- IsoSciences, LLC

- IUL Instruments

- Micropore Technologies

- Matrix Innovation

- PreciGenome

- PhylumTech

- ProFoldin

- Protein Ark

- Primer Design

- ProteoChem

- RareCyte

- RECIPE

- Silicycle Inc.

- Tymora Analytical

- UTAK

- YouSeq

- Z Biotech

- E-PAK® 소개 및 선택 가이드

- 제품명: E-PAK® 소개 및 선택 가이드

- 용도: Fixed Bed Flow-Through Purification Cartridges

- 메이커: Silicycle Inc.

- 카달로그:

소개

E-PAK® Fixed Bed Flow-Through Purification Cartridges

E-PAK is a family of radial flow adsorption cartridges developed specifically for pharmaceutical processing.

Offered with a choice of metal scavengers, bare silica & activated carbons, these cartridges are designed to

remove precious metal catalysts, reaction-by-products or color from synthetic reaction mixtures and natural products.

• Easy Scale-Up

From laboratory to industrial production

• Proven Technology

Proven cartridge design & reliable technology

• Performance

High adsorption capacity & flow rate

• Convenience

Safer handling, clean-up & disposal

• Optimization

Increases product recovery & reduces solvent requirements

• Various Sorbents Offered

SiliaMetS Metal Scavengers, Bare Silica & Activated Carbons

E-PAK Cartridges Portfolio

E-PAK Cartridges are offered in 3 formats:

Lab ScalePilot ScaleCommercial Scale

With 3 types of sorbents :

• SiliaFlash irregular silica gels

40 - 63 µm

60 - 200 µm

200 - 500 µm

• Metal Scavengers

SiliaMetS Thiol

SiliaMetS DMT

• Activated Carbons

C941

C-947

C948

We also offer a range of housings for each cartridge format :

Available Sorbents

| Active Adsorbents | For Removal and/or Recovery of : | pH Operation |

|---|---|---|

| SiliaMetS Thiol | Pd, Ag, Hg, Os, Ru, Cu, Ir, Pb, Rh, Se & Sn | 2 to 10 |

| SiliaMetS DMT | Pd, As, Ir, Ni, Os, Pt, Rh, Ru Se, Cd, Co, Cu, Fe, Sc & Zn | |

| SiliaMetS Imidazole | Cd, Co, Cu, Fe, Ir, Li, Mg, Ni, Os, W, Zn, Cr, Pd & Rh | |

| SiliaBond Amine | Pd, Cr, Pt, W, Zn, Cd, Co, Cu, Fe, Hg, Ni, Pb, Ru, Sc & Se | |

| SiliaMetS Diamine | ||

| SiliaMetS Triamine | ||

| SiliaFlash Bare Silica | Very vast range of organic impurities, metals, pigments... | 2 to 9 |

| Activated Carbons | Precious metal catalysts & colors | 1 to 13 |

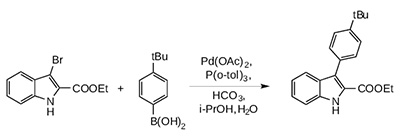

Scale Up

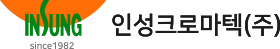

One of the strongest benefits of SiliCycle E-PAK Cartridges is their linearity upon scale-up.As shown below, in a typical Suzuki-Miyaura coupling for which palladium needed to be removed, each format behaved very similarly in terms of efficiency (scavenging %), kinetics and relative capacity.

|

Experimental Conditions

|

|||

|---|---|---|---|

| E-PAK Format | Bead volume (mL) | Flow rate (mL/min) | Residence Time (min:sec) |

| 5 cm x 1 cm | 18.8 | 10 | 01:53 |

| 5 cm x 12 cm | 188 | 100 | 01:53 |

| 5 cm x 25 cm | 470 | 250 | 01:53 |

| 16.5 cm x 25 cm | 4,750 | 2,600 | 01:50 |

| 16.5 cm x 100 cm | 19,000 | 10,400 | 01:50 |

Once the best purifications sorbents have been identified in bulk, transferring the conditions from bulk to cartridges can be a very robust strategy for rapid and efficient scale-up.

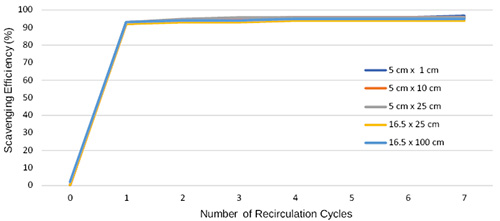

Various Ways of Using E-PAK

Depending on the application and how you prefer to work, E-PAK cartridges can be used in different ways as shown below.

For a single pass usage, we suggest to run at very low flow rate compared to recirculation process, which can be run at higher flow rate.

Flow & Hydraulic Pressure Drop

Cartridges provide rapid kinetics at flow rates and contact times suitable for single pass operation. The chart below shows typical flow rates and pressure drop performance for Lab, Pilot and Commercial Scale Cartridges.

| Cartridge Size (diameter x height) |

Minimum Flow Rate | Maximum Flow Rate | Pressure Drop ΔP (Psig) with w/1 cps Fluid |

| 5 x 1 cm (Lab) | 5 mL/min | 100 mL/min | ≤ 7.5 psig |

| 5 x 10 cm (Lab) | 50 mL/min | 500 mL/min | ≤ 5 psig |

| 5 x 25 cm (Lab) | 125 mL/min | 1 L/min | ≤ 5 psig |

| 16.5 x 12.5 cm (Pilot) | 0.95 L/min | 2.5 L/min | ≤ 10 psig |

| 16.5 x 25 cm (Pilot) | 1.9 L/min | 5 L/min | ≤ 10 psig |

| 16.5 x 50 cm (Commercial) | 3.8 L/min | 10 L/min | ≤ 10 psig |

| 16.5 x 100 cm (Commercial) | 7.6 L/min | 20 L/min | ≤ 10 psig |

Chemical Compatibility

E-PAK cartridges are formed using a proprietary technology and chemically stable materials in common organic solvents.

E-PAK cartridges have been tested and found satisfactory for use with the following commonly used solvents:

• Methanol

• Dichloromethane

• Ethyl acetate

• Tetrahydrofuran

• Toluene

• N-ethyl-2-pyrolidone

E-PAK cartridges are suitable for operation at pH of 1 to 13 for activated carbon and 2 to 12 for silica-based products.

Handling and Safety

Initial solvent wetting of E-PAK cartridges will produce heat; a risk assessment with the use with low vapor pressure solvents is recommended.

The adsorbent matrix in E-PAK cartridges is electrically conductive. E-PAK cartridges filter housings and retrofit kits provide a connection between the adsorbent matrix and the filter cartridge housing. A risk assessment of electrical discharge in explosion proof environments is recommended.

Quality and Regulatory

E-PAK cartridges are manufactured under ISO 9001, GMP manufacturing operations in Glasgow, DE (U.S.A.).

Drug Master File registrations are in progress.

동영상

관련자료