Solutions

솔루션

점도

세계 유일의 마이크로 유체 및 MEMS 기술 기반 미량 시료 점도 분석 home

home- > 솔루션 >

- 점도

|

[점도] Cannabis Oil

인성크로마텍

|

| Date : 2019.11.26 |

| 분류 : 생체의약품 |

Cannabis Oil Viscosity: Dependence on Composition and Temperature

Key Words: Viscosity, THC, CBD, Cannabis, Temperature Sweep, Cannabinoid, Cannabidiol, Tetrahydrocannabinol, Arrhenius Behavior

Summary:

This application note presents temperature dependent viscosity data for two cannabis oils with varying levels of CBD and THC. Measurements were performed by manually injecting 50µL of each sample into VROC® initium with the temperature range of 40 to 70°C.

Introduction:

Viscosity, which depends significantly on temperature, is a critical parameter to predict both the process ability and application performance of any fluid. A cannabis oil will be exposed to a broad range of temperatures as it moves through the manufacturing process and then onto the end user. Therefore, a proper rheological characterization of cannabis oils must include temperature variation. The viscosity of two commercially available oils was measured as a function of temperature with the VROC® initium. The temperature dependence was reasonably characterized by the Arrhenius law. Model fit parameters can be used to interpolate and estimate the viscosity at other relevant temperatures.

Experiment:

Viscosity measurements were performed on two commercially available cannabis oils with the VROC® initium. The measurements were made in automatic mode as the temperature was ramped down to 40°C. Shear rate decreased with increasing viscosity and ranged from 1113 to 40 sec-1. Only 50 μL of each sample was required for the full temperature sweep using the C05 flow channel (Pmax = 200 kPa, depth = 50 mm).

♣ Measurement Tip: With highly viscous samples, like these, it is much easier to load samples that are heated up. Prior to picking up the sample the syringe and the sample were heated up to 70°C.

Viscosity Data and Discussion:

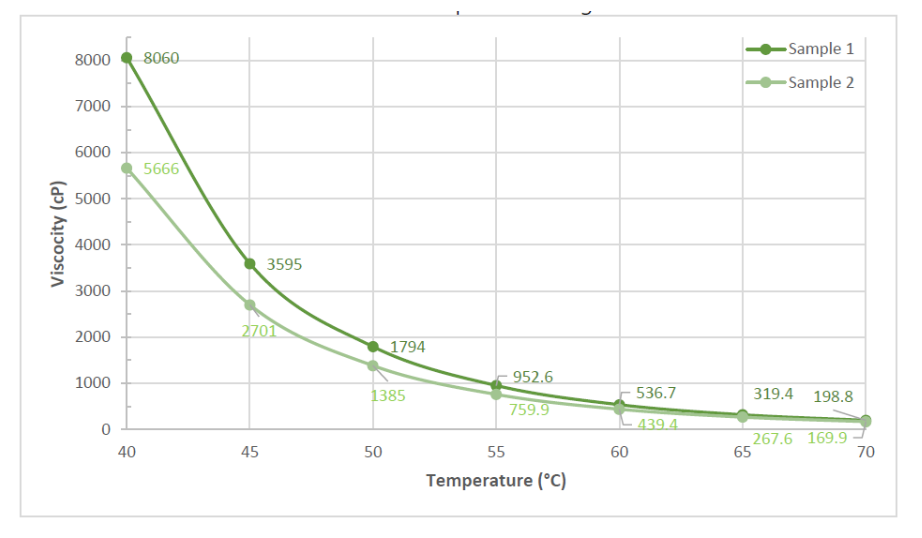

Figure 1 clearly illustrates that there is a significant change in viscosities from 70°C to 40°C. The “Sample 1” sample had a viscosity of 198.8 cP at 70°C but shot up to 8060 cP at 40°C. That results in a factor of 40.5 difference in viscosities over a 30°C temperature range.

Figure 1: Viscosity versus temperature for cannabis oil samples

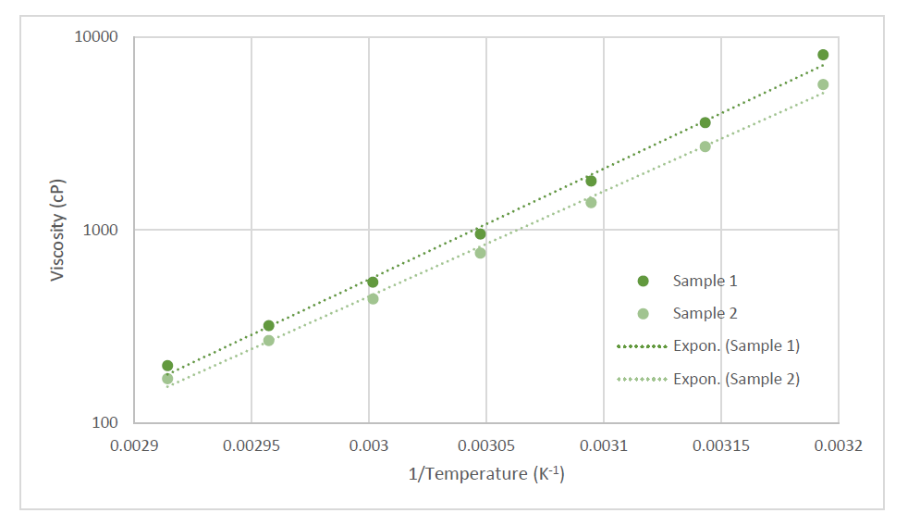

The “Sample 2” sample had a similar trend with a viscosity of 169.9cP at 70 ºC and a viscosity of 5666 cP at 40 °C. That is a factor of 33.3 difference in viscosity over a 30°C temperature difference. Both samples are stated to be 100% Cannabis Oil that was extracted using CO2. They differ though in the THC and CBD concentrations; the “Sample 2” sample was 80% THC and 0% CBD while the “Sample 1” sample is 78% THC and 0.29% CBD. The differences in THC and CBD percentages are probably a contributing factor, along with additional compounds that were extracted, to the differences in viscosities between the two samples. There is also an Arrhenius behavior of the viscosity that can bee seen in Figure 2. The x-axis is the inverse of the temperature in kelvin

while the y-axis is the viscosity in cP but scaled logarithmically. We were able to evaluate the data in this way thanks to the RheoSense Clariti™ software. Along with the graph, Clariti was able to calculate the activation energy and R2 of both samples using Equation 1.

a R2 of 0.9965.

Equation 1: Arrhenius Equation

Figure 2: Arrhenius Behavior of Cannabis Oil

Concluding Remarks: Viscosity is not just one single number but instead can drastically differ based on various factors including temperature. The viscosity of cannabis oil appears to differ drastically depending on the temperature of the sample. This temperature dependence is an important consideration in the manufacturing of cannabis oil because it will go through a variety of temperature during its use and all of this can be measured with ease thanks to the VROC® initium.

|